Publikálva:

M. NEMÉNYI – A. LŐRINCZ (2002): Appreciation

of an complex ultrasound system according to survival

cell count. Hungarian Agricultural Engineering.

APPRECIATION OF AN COMPLEX ULTRASOUND SYSTEM

ACCORDING TO SURVIVAL CELL COUNT

Summary

The decreasing of micro-organism

cell count the most important task of the food industry. The killing of microbe no too

difficult thing rather the preserve of essential food components is the heavey

work. The modern microbe destructor technologyes its effects

goals only the pointed objects and dont touchs the other essential food

components. Our experimental work goals this philosophy with ultrasound.

We examinated the surviving cell count of Saccharomyces cerevisiae suspension.

This cell suspension was of an closed liquid circuit

system streaming with peristaltic pump. The cell count with manual and

automatical detection system was examinated and the experimental method based

on vital staining with methylen blue and on the cell counting. The results gives possibility any cell phase analytical and

continuous cell decreation system developing. This work is fundamental

research.

Introduction

There is no cavitation

in the ultrasound field until the amplitude of the acoustic pressure exceeds a

certain level, the cavitation threshold [1]. Cavitation threshold is

proportional with the frequency of ultrasound, with the hydrostatic pressure in

the liquid, and with the viscosity of the sample and it is inversely

proportional with the gas content and

temperature of the sample [2]. There are two types of cavitation that are

stable and transient cavitation [3]. Basically two reactions take place when ultrasound and a media

interact with each other. One of them is the absorption the other one is the

scattering, which changes e.g., the speed of propagation of the sound in the

subject media [4]. Due to the absorption, the intensity of ultrasound decreases

exponentially with distance and the absorption coefficient primarily depends on

the speed of propagation of the sound in the subject media, on the wave type,

on the material situated in the ultrasound field and on the frequency. The

absorption always characterizes a media, a structure or an environment that

determines the parameters of propagation [5]. When absorption coefficients were

measured in oxo- and és methemoglobin, it was observed that the absorption is

proportional with the concentration of hemoglobin in the concentration range

between 0 and 15 [g/100ml] [6]. It

was clearly established that the profile of the ultrasound propagation

speed depends on the concentration profile of the suspension [7]. Effects of

the size and concentration of the suspended particles on the propagation speed

of ultrasound was examined in water based suspensions. It was established that

the speed of sound largely depended on the particle size and concentration [8].

In vitro cavitation threshold measurements were carried out in human blood. In

the fresh blood that contained every blood component, the amplitude of the

acoustic pressure belonging to the cavitation threshold was higher than in

diluted blood [9]. Due to cavitation caused by ultrasound, acoustic streaming

was formed in the liquid [10]. Acoustic streaming is a movement of the liquid

that is caused by intensive ultrasound [11]. Mixing of liquid was experienced

in the ultrasound field due to acoustic streaming [12]. An acoustic reflector

placed opposite to the transducer causes a standing wave to be formed. In a

standing wave the materials whose density are lower and higher than of the

liquid drift to propagation cluster planes (pressure antinodes), and pressure

nodes, respectively [2]. The ultrasonic separation is used in analytical

biotechnology applications. This procedure is based on the fact that in a

standing wave field, where there is no cavitation, the cells are arranged in bands

distances of which are smaller than a millimeter and they can be separated from

these bands [13]. Yeast (Saccharomyces cerevisiae) and rubber particles

were manipulated in a standing wave ultrasound field at frequencies of 1 and 3

[MHz]. The particles formed bands in pressure nodes whose distance from each

other was equal to half of the wavelength. In the direction of the radiation

the bands formed column like structures. Stability of the bands, the conditions

under which they are broken and the formation of the acoustic streaming were

investigated in [14]. Effectiveness of the cell separation of Escherichia

coli bacteria and Saccharomyces cerevisiae yeast cells from a yeast

suspension was examined at frequencies of 1 and 3 [MHz] [16].

Materials and methods

As

experimental marker microorganism we suspended 1,8

gram yeast (Saccaromyces cerevisiae) in

200 cm³ distilled water with a magnetic mixer until it became clod free

and the cell concentration reached the level of 9x107/ml. For the

sake of a better detection we put 5 drops of methylene blue into the solution,

which did not influence the vitality of the microorganism.

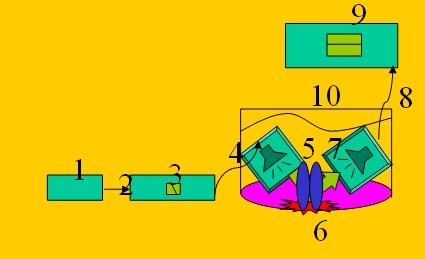

We put the suspension into a fluid flow system (Fig. 1.) of 116 cm3

of inner volume with a peristaltic pump. After the filling and short-circuit of

the system the suspension was circulated by a peristaltic pump between the

different structural units. The suspension was then not directly treated but

isolated from its environment by material flow through ultrasonic flow cuvettes

(Fig. 2.) especially made for this purpose. The ultrasonic cuvettes allow the

suspension to flow with a surface of 1 cm2 and a thickness of 0.5 mm. There were two cuvettes placed 1 cm apart at right

angles to the flow direction. The reason for this arrangement was that the

effects on the liquid film are much easier to observe than inside the material.

In order to avoid cell

sedimentation an efficiently high rate of flow was applied: 50-70 cm/sec (4-5

cm3/sec). The suspension flowing in the ultrasonic cuvettes were

exposed at a frequency of 0.8 MHz and at a capacity of

10 W/cm2. The suspension

flowing in the system gets into an optical detection cell placed in a

biological microscope. The picture gets then from here through a CCD camera

into a computer system, where it will be saved according to time units. Which

will allow evaluating the cell disruption effect of the treatment based on

calibration. After short-circuit the flow system and turning on the ultrasonic

system there were drop samples taken at time units through a built-in tap. The

samples were immediately analyzed under a Bürker chamber. A thermostat unit also belongs to the system,

which ensures a constant temperature for the reproduction of the tests.

The survive cell analysis is based on a vital stain, which means that

under microscope with Bürker-chamber. The dead cells are stained blue owing to

methylene blue but the living organisms remain clear. We can establish the

curve of deteriorated and survived cells owing to ultrasonic treatment as blue

stained and clear cells are counted at regular time units. Organisms are

regarded as cells, which have

intact cell walls and reflect vitality. We want to mention this

fact because after a certain time of treatment cell lysis will happen.

Treatment definition

The treatment

means a certain period of time during which the amount of liquid circulating in

a flow system is exposed to a physical (ultrasonic) treatment of a given

capacity during a given period.

The time of

treatment means in the flow system the period between the turning on and

turning off the ultrasound. This period was taken into account during the

evaluation of the results.

As for the

amount of liquid the time of treatment had to be corrected in the flow system

concerning the total amount of liquid flowing in the system and the total time

of treatment. Therefore the total liquid treatment time of „A”

is required to reduce the original cell

count to its hundredth where „B”=116cm3 is the total amount of flowing liquid in our system. So 1 cm3

of cell suspension has to be treated at „A/B” minute.

Results and discussion

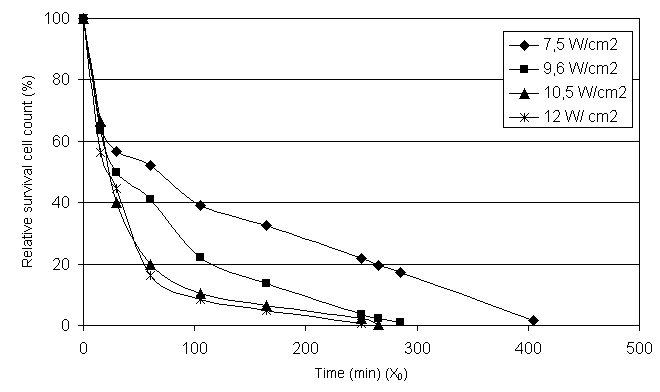

Treatments

were carried out at 0,8 MHz and with a capacity of 7,5

W/cm2; 9,6 W/cm2; 10,5 W/cm2 and 12 W/cm2

by taking samples from the suspension at defined times. These samples were then

evaluated in Bürker chambers based on the average living and dead cell numbers

to be observed. Figure 3 showed the relative percentage of survive cell counts

in the samples. According our examinations the relative surviving cell counts

of one milliliter treated suspension showed on table 1. On fig. 3. the ♦ = 7,5 W/cm2, ■ = 9,6 W/cm2,

∆ = 10,5 W/cm2, X = 12 W/cm2 are the points

belonging to the ultrasonic treatments

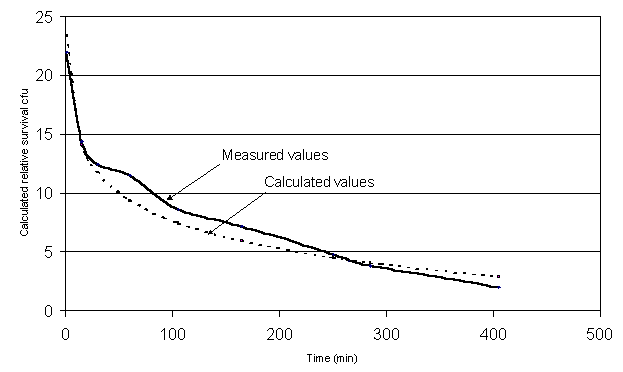

and the functions fitted to them (Fig 4.). The relative living cell

counts signified by the different symbols show that more drastic and faster

cell destruction is to be observed depending on the time passed if we applied

higher capacities. In table 1 the relative cell counts refer to 22 cells per

Bürker chamber owing to creating the model function, which indicate an initial

cell count of 88 million/millilitre. In

order to set up a model formula we set different trend functions onto the

points. The logarithmic trend functions showed the highest correlation with the

measured points. Setting trend functions on to the additive and multiplying

factors of the logarithmic functions resulted in the formula shown in table 2.

where „a” is the trend function referring to the additive factor and „b” is the

trend function referring to the multiplying factor. Cell count can be omitted from the

model formula as it refers to the initial cell count of 22 cells/Bürker chamber

(cfu), so it has to be corrected by the actual cell counts respectively. This model

function helps to calculate the ultrasonic capacity that is required for

treating the material at a given initial cell count, so that it would reduce to

the required cell count after a certain period of time. Or it allows

determining the time needed to reach the required cell count at constant

ultrasonic capacity. Of course these values refer to a given system. Therefore

a correction factor is to be used for a general usage adapted to the actual

conditions. Figure 5. shows the

replacement of the treatment of 7.5 W/cm2.

Conclusion

The model function allows modelling the

effects of the ultrasonic treatment at a frequency of around 0,8 MHz and different capacities.

The

ultrasonic treatment can be adapted for use for treating agricultural products

if high quality is required.

Acknowledgement

We express out thanks

for the help of Prof. Dr. Pál Greguss from the Technical and Economic

University of Budapest.

References

[1] F. J.

Fry, Ultrasound: Its Applications in Medicine and Biology, Elsevier Scientific

Publishing Company, Amsterdam-Oxford-New York. 1978

[2] G.R. Ter Haar, Biological Effects of Ultrasound in Clinical

Applications. In: S.K. Suslick, Ultrasound, Its

Chemical, Phisical, and Biological Effets. VCH Verlagsgesellschaft mbH, Weinheim.

1988 pp 305-319.

[3] L.A Frizzel, Biological Effects of Acoustical Cavitation. In.: S. K. Suslick, Ultrasound, Its Chemical, Phisical, and

Biological Effets. VCH Verlagsgesellschaft mbH, Weinheim. 1988 pp 287-301.

[4] C.R. Hill,– R.C. Chivers,– R.W. Huggins,– D. Nicolas,

Scattering of Ultrasound by Human Tissue. In.: F. J.

Fry, Ultrasound: Its Applications in Medicine and Biology. Elsevier Scientific

Publishing Company, Amsterdam-Oxford-New York 1978 pp 441-493.

[5] H.

Kurtuff, Ultrasonics Fundamentals and Applications, Elsevier Applied Science,

London and New York. 1991

[6] E.L. Carstensen, H.P. Schwann,

Acoustic Properties of Hemoglobin Solutions, J. Acoust. Soc. Amer. 31 1959 p

305.

[7] D.J. Wedlock, C.J. McConaghy, S.

Hawksworth, Automation of ultrasound velocity scanning for concentrated

dispersions, Colloisd and Surfaces A: Physiochemical

and Engineering Aspects. 77 1993 pp 49-54.

[8] P.

Sayan, J. Ulrich, The effect of particle size and suspension density on the

measurement of ultrasonyc velocity in aqueous solutions, Chemical Engineering

and Processing. 41 2002 pp 281-287.

[9] C.X. Deng, X. Quihong, R.E. Apfel, C.K.

Holland, In vitro measurements of inertial cavitation thresholds in human

blood, Ultrasound in Med. and Biol. 22 1996 pp 939-948.

[10] A.H. Saad, A.R. Williams, Possible

mechanisms for the agitationinduced enhancement of acoustic cavitation in

vitro, J. Acoust. Soc. Am. 78 1985 pp 429-434.

[11] H.

Mitome, The mechanism of generation of acoustic streaming, Electronics and

Communications in Japan, Part 3. 81 1998 pp 1-8.

[12] D.J. Watmough, K.M. Quan, M.B. Shiran, Possible explanation for the unexpected absence

of gross biological damage to membranes of cells insonated in susupension and

in surface culture in chambers exposed to standing and progressive wave fields,

Ultrasonics. 28 1990 pp 142-148.

[13] W.T. Coakley, Ultrasonic separations in analitical

biotechnology, Trends in Biotechnology. 15 1997 pp 506-511.

[14] J.J. Hawkes, J.J. Cefai, D.A. Barrow, W.T. Coakley, L.G. Briarty, Ultrasonic manipulation of particles in

microgravity, J. Rhys. D: Appl. Phys. 31 1998 pp 1673-1680.

[15] J.J. Hawkes, M.S. Limaye, W.T. Coakley, Filtration of bacteria and yeast by ultrasound

enhanced sedimentation, Journal of Applied Microbiology. 82 1997 pp 39-47.

Figure 1.

The complete flow injection system. Key: 1. Peristartic pump, 2. Lead out tube,

3. Ultrasonic treating cuvettes, 4. Tube, 5. Tap 6. Optical flow cuvette, 7.

Lead in tube, 8. Stereomicroscope, 9. CCD camera, 10. Ultrasound transmitter,

11. Ultrasound receiver, 12. Echoless waterbath.

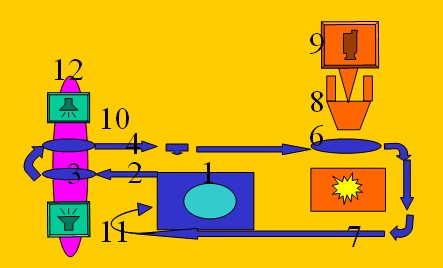

Figure 2.

The ultrasound system. Key: 1. Signal generator, 2. Electronic cable, 3.

Ultrasound amplifier, 4. Electronic cable, 5. Ultrasound transmitter, 6.

Reflection surface, 7. Ultrasound receiver, 9. Electronic cable, 9.

Oscilloscope, 10. Echoless watertank.

Table 1.

Relative surviver cell cell counts of one millilitre treated cell suspension

after different exposition times.

|

Ultrasound power Exposition time |

7,5 [W/cm2] 4 min 3

sec |

9,6 [W/cm2] 2 min 51

sec |

10,5

[W/cm2] 2 min 39

sec |

12 [W/cm2] 2 min 30

sec |

|

Rel

surv. Cell count |

1,7% |

0,9% |

0% |

0,8% |

Figure 3.

Relative survival cell

count (%)

Figure 4. Relative survival cfu

Table 2. Complete

model function modelling the ultrasonic treatment of liquid suspensions

|

y=a*lnx0+b (x0=time, [min]) |

|

a=-1.9376*lnx1+0.4753 (x1= Ultrasound power, [W/cm2]) |

|

b=-1.5277*lnx1+26.567 (X1=

Ultrasound power, [W/cm2]) |

Figure 5.

Model function in relation to the real values